Author:Poultry Industry Section,Department of Animal Industry,Council of Agriculture,Executive Yuan

Sensors are installed in poultry houses to collect data to be transmitted to the database for graphic display.

Sensors are installed in poultry houses to collect data to be transmitted to the database for graphic display.The poultry industry accounts for about one-third of the output of the livestock and poultry production in Taiwan. It is, however, still operated mainly by small farmers using traditional methods with no comprehensive records kept of the production process. Some large companies integrate hatching, feed producing, and processing in a whole production line, with only limited extent of intelligence involved, however, to effectively and stably raise the productivity and yield rates. In recent years, the lack of labor force due to the aging farming population, coupled with the shortage of management professionals in the livestock and poultry industry, has made it difficult to collect relevant data, let alone to construct a growth management or traceability system. Yuan Jin Chuang Smart Poultry Farmers Alliance coordinates small farmers in using intelligent technologies in all stages of production, including incubation, breeding, slaughter, processing and marketing. The work involves the development of smart poultry houses, diversified products and marketing channels, and the traceability system so as to reach higher production efficiency and quality, reduce the risk of imbalanced production and marketing, and enhance competitiveness. At the center of the alliance, Yuan Jin Chuang Foods has developed smart breeding systems for waterfowls and poultry, and assisted contract farmers to jointly invest in smart breeding equipment. The plan is to introduce smart breeding equipment to all the contract farmers in the next three years and to realize a whole smart production line system.

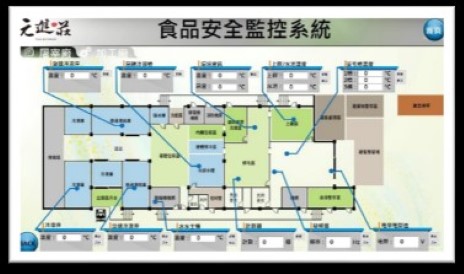

The intelligent waterfowl and poultry breeding system is a joint effort of enterprises of IoT equipment, system integration, big data, etc. It is based on the rich experience of poultry breeding and the construction of smart poultry houses to use various sensors to automatically detect the temperature, humidity, gas concentration, wind speed, dew point, drinking water volume, feed volume, weight, etc. Adjustment is automatically made when abnormalities are found to achieve the optimal breeding conditions. Advance projected/planned production is thus made possible for the optimization of productivity and efficiency. Recently, the entire poultry house construction has been standardized, and a standardized operating procedure (SOP) for poultry farming has been established. There are now standardized modules for poultry houses suitable for operators in Taiwan and Southeast Asia, which are ready for package plant export. Besides, to raise the production efficiency and quality and to prevent disease outbreaks and ensure food safety, Yuan Jin Chuang slaughterhouse and processing plants have the food safety monitoring system to record detailed information of each stage of the production line. The traceability system is introduced to keep track from the initial stage of breeding and incubation. The fledglings are sent to contract poultry farmers for cultivation, with the feed supplied from a centralized source. Detailed information on the temperature, water quality, and feeding amount during the breeding is recorded to ensure the breeding traceability.

The food safety monitoring system can record the detailed information of each stage of the production line, including the slaughtering and processing. Alarms will be issued if any abnormality is detected.

The food safety monitoring system can record the detailed information of each stage of the production line, including the slaughtering and processing. Alarms will be issued if any abnormality is detected.The alliance itself is a project of open innovation. With the core in innovation, the aim is value creation for small poultry farmers. Raising poultry like chickens, ducks and geese used to be regarded as a tedious labor-intensive industry, which young people found discouraging. Now with the intelligent technologies introduced, there is better effect of disease prevention and control, and the breeding rate has increased by more than 5%. The data in the breeding process are collected for centralized management and the improvement of the traceability system. Through the smart management APP, convenient remote control is possible with just a mobile phone. Young farmers now are more willing to engage in the poultry industry. The farmers are ensured of maximum benefits and interests by the guaranteed purchasing system. At the same time, as an incentive for the contract farmers, the cost of the equipment is reduced with most of it made domestically. It is estimated that the cost invested in a smart poultry house with 20,000 birds can be recovered within three years.

"From small farmers to a big brand name; from farms to the dining table." Yuan Jin Chuang Foods currently has about 4 million native chickens and 2 million ducks cultivated by contract farmers. It is actively engaged in raising the value of the poultry industry by controlling the quality of breeding and incubation at the initial stage, the promotion of the correct cultivation and epidemic prevention concepts among the contract farmers, the guaranteed price purchasing, and assisting in the upgrading of smart production technologies, thereby effectively minimizing imbalances in production and marketing and the consequential price fluctuation to ensure the farmers of stable and optimized benefits. This also helps bridge the gaps found in the chain of production and supply so that all contract farmers are devoted to sustained development. This practice echoes one of the global development goals advocated by the United Nations: "Responsible Consumption and Production." The overall stability of supply and quality of poultry products is raised through intelligent system management to provide the consumers with safe and secure poultry products of good quality.